2175008 - SUMMA NOVA FR Hi-Vis Jacket

Gallery

Click to enlarge · Swipe to switch

Details

SUMMA NOVA 2175008 · FR Hi-Vis Jacket

Keywords

Flame-resistant · Arc flash protection · Hi-Vis FR jacket · EN ISO & NFPA compliant · Industrial safety outerwear

Basic Information

- Product Code: 2175008

- Series: F = FR (Flame Resistant)

- Cost Anchor: USD $46 – $58 / pc (FOB base specification, estimated)

- Colorways: Fluorescent yellow main body with FR segmented reflective trims

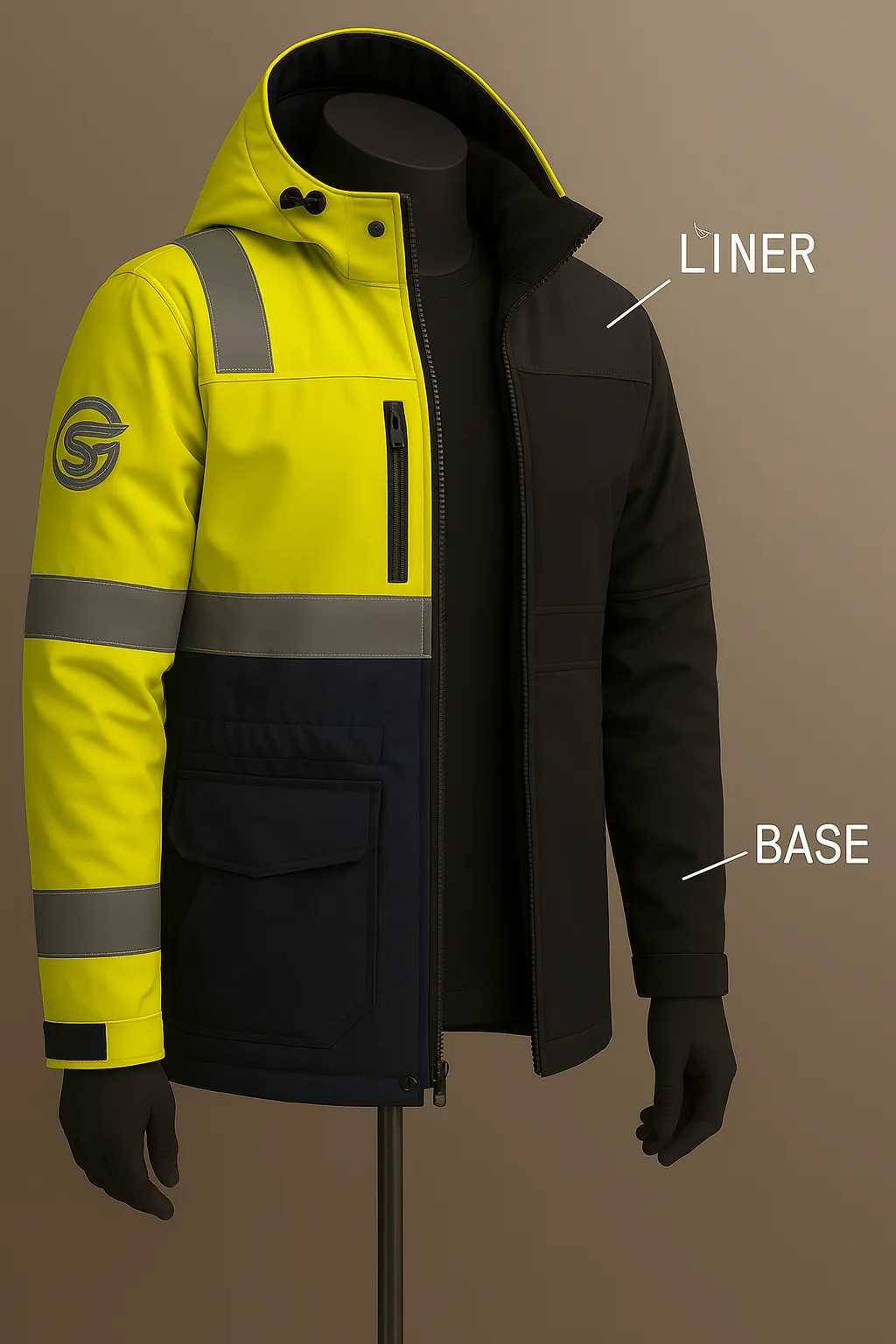

- Positioning: Four-season outer shell designed for FR/Hi-Vis integration, compatible with SUMMA Zip-in liner system

Application Scenarios

• Municipal and sanitation operations

• Road and public works

• Airport ground handling and maintenance

• Logistics and courier services

• Construction and infrastructure projects

Technical Highlights

- Certified to EN ISO 11612, NFPA 2112, NFPA 70E, and EN ISO 20471 Class 3 for dual FR + Hi-Vis protection

- 7 oz (≈240 gsm) FR 88/12 twill shell — durable, breathable, and compliant for industrial use

- Water-repellent finish with FR internal mesh lining for comfort and moisture management

- FR segmented reflective tapes — wash-durable and arc-safe, placed across torso, sleeves, and shoulder yoke

- Ergonomic patterning with pre-curved sleeves for mobility and unrestricted reach

- Reinforced seams with Nomex® FR thread and bar-tacks at stress zones

- Zip-in system ready — compatible with SUMMA mid-layer liners for 4-season versatility

4. Materials & Trims

- ensp;Shell Fabric: 7 oz (≈240 gsm) FR 88/12 cotton / nylon twill — inherent flame-resistant, anti-shrink finish

5. Structure & Functional Design

- ensp;Regular fit silhouette with an extended back hem for enhanced coverage and ergonomic sleeve construction ensuring unrestricted mobility

- ensp;Front closure features a flame-resistant zipper with double storm flaps and concealed Hook-and-loop closure fastening for improved wind and rain protection

- ensp;Two lower cargo pockets with flaps, one left chest zip pocket, and one internal utility pocket with a dedicated pen slot provide practical storage solutions

- ensp;Detachable three-piece hood with adjustable drawcord and reinforced visor brim offers reliable head protection in variable weather

- ensp;Adjustable cuffs with FR Hook-and-loop closure and an elasticized hem drawcord deliver comfort and wind resistance

- ensp;Underarm eyelets combined with a breathable mesh lining ensure optimal ventilation and sweat evaporation during extended use

- ensp;5 cm FR segmented reflective tapes are applied across torso, sleeves, and shoulder yoke in compliance with EN ISO 20471 Class 3 geometry for maximum visibility

- ensp;Zip-in ready modular system is compatible with SUMMA DEFENDER (Fleece) and PIONEER (Light Padded) mid-layer liners for four-season adaptability

6. Market Benchmarks References

-Helly Hansen / Mascot / Blåkläder — European FR Hi-Vis workmanship & reflective geometry

-Carhartt / Dickies — Rugged construction & everyday usability

-Cintas — Uniform-grade durability & logo-ready customization

-3M™ Reflective — Wash-durable FR reflective performance

7. Selling Messages

- ensp;All-weather visibility · Dual-certified FR + Hi-Vis protection

- ensp;Rainproof and breathable · Designed for extended wear comfort

- ensp;Ergonomic mobility · Pre-curved sleeves and modular fit

- ensp;Zip-in system · Compatible with SUMMA mid-layer liners for 4-season versatility

- ensp;Professional-grade durability · Ideal for energy, logistics, and public works sectors

8. Function – Design – Validation

| Function | Design | Validation |

|---|---|---|

| FR protection | 7 oz FR 88/12 twill shell; Nomex® FR thread; non-conductive trims | EN ISO 11612; NFPA 2112; NFPA 70E / ASTM F1506 |

| Hi-Vis compliance | 5 cm FR segmented reflective tapes; torso/arms/shoulder layout | EN ISO 20471 Class 3; wash-durable retroreflective performance |

| Weather & comfort | Water-repellent finish; breathable mesh lining; underarm eyelets | Spray/penetration resistance; MVTR/breathability checks |

| Mobility & ergonomics | Pre-curved sleeves; extended back hem; adjustable cuffs/hem | Fit trials; range-of-motion validation |

| Durability | Triple-stitched seams; bar-tacks at stress zones | Abrasion, tear, and seam-strength tests |

| Modularity | Zip-in ready with SUMMA DEFENDER (fleece) / PIONEER (Light Padded) | Interface inspection; attachment cycle tests |

9. Retro-Reflective Area (M size example)

Chest & Waist Rings: 1250 cm² · Sleeve Bands: 450 cm² · Continuous Shoulder: 260 cm²

Total: 1960 cm² (≈ 0.196 m²)

Compliant with EN ISO 20471 Class 3 and ANSI/ISEA 107 Type R, Class 3 visibility requirements.

10. Compliance & Quality Assurance

-Material Compliance: All shell, lining, and trim materials must comply with OEKO-TEX® Standard 100 Class II requirements, with supplier certificates and valid test reports provided.

-Testing & Performance: Key fabrics must undergo third-party testing for flame resistance, tensile and tear strength, abrasion resistance, colorfastness, and dimensional stability, with compliance reports referencing EN ISO, AATCC, or ASTM standards.

-Workmanship Standards: Stitch density, seam construction, and seam allowances must comply with international workwear standards, with triple-stitching and bar-tacks applied at all critical stress points.

-Labels & Care Instructions: Labels must include size, supplier, production date, material composition, and ISO 3758 care symbols, attached at regulated locations (e.g., back neck or side seam).

-Packaging: Each garment must be individually packed in recyclable polybags. Cartons must be clearly marked with SKU, size, color, origin, PO number, and barcodes.

-QA Documentation: Supplier must provide all relevant compliance documentation — including OEKO-TEX® certificates, performance test reports, and batch QA records — prior to shipment.