2175007 - SUMMA GUARDIAN FR Coverall

Gallery

Click to enlarge · Swipe to switch

Details

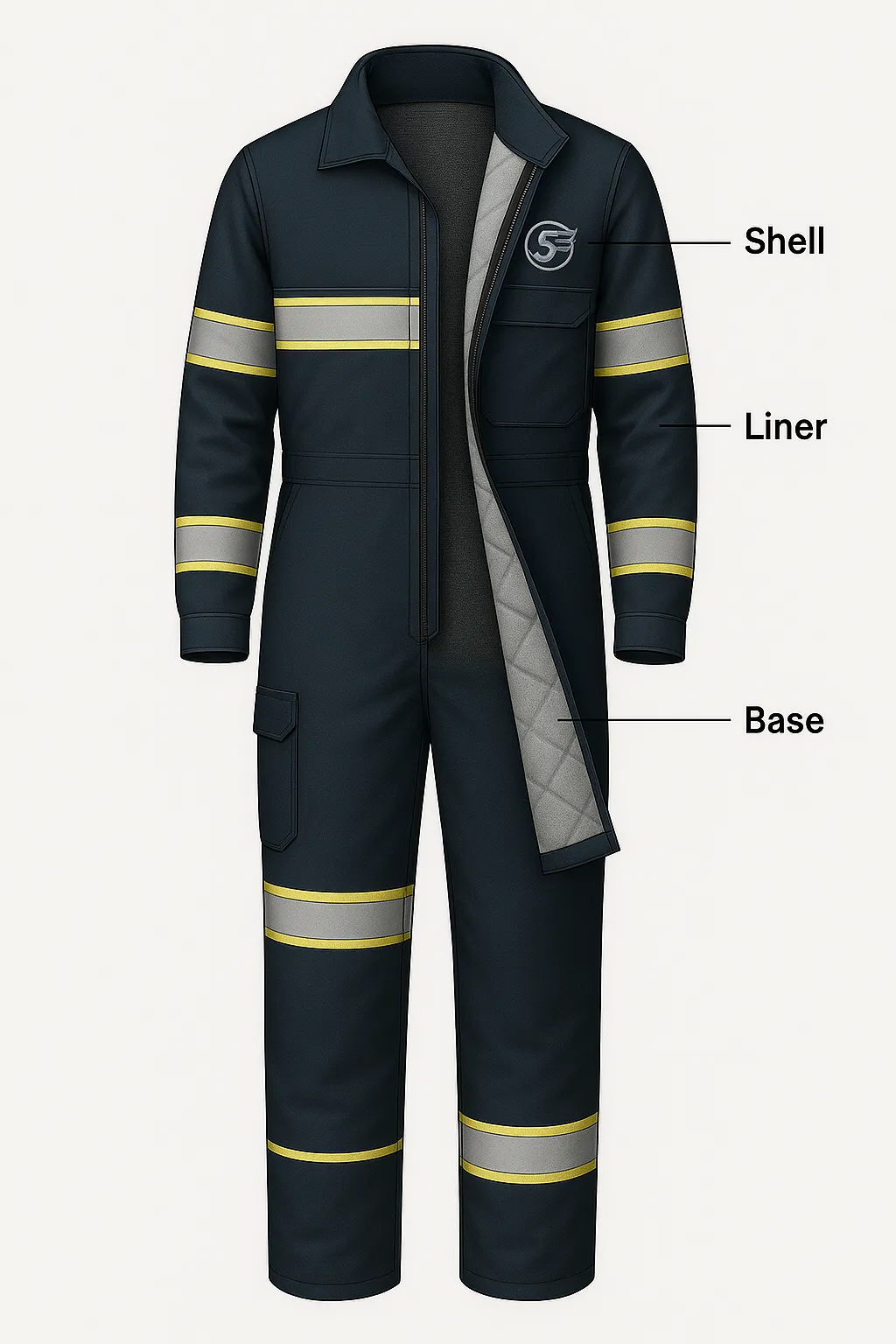

SUMMA GUARDIAN 2175007 · FR Coverall

Keywords

Flame-resistant , Arc flash protection , Industrial coverall , EN & NFPA compliant

Basic Information

- Product Code: 2175007

- Series: FR (Flame Resistant)

- Cost Anchor: USD $38 – $48 (FOB base spec, est.)

- Colorways: Navy / Orange / FR Yellow

- Positioning: Industrial-grade FR coverall providing full-body protection for oil, gas, energy, and maintenance environments

Application Scenarios

• Municipal and sanitation services

• Road and public works

• Airport ground handling

• Logistics and courier operations

• Construction, energy, and infrastructure industries

Technical Highlights

-Certified to EN ISO 11612 / NFPA 2112 / NFPA 70E – dual-standard FR protection

-Arc-rated fabric (CAT 2 / ATPV ≥ 8–12 cal/cm²) for electrical safety

-7oz–9oz FR cotton/nylon twill – durable, comfortable, and breathable

-Full-body protection with double-stitched seams and stress-zone reinforcement

-FR zippers, threads, and trims – metal-free design for electrical insulation

-Optional reflective tape for enhanced low-light visibility

-Elastic waist & ergonomic cut improve range of motion for industrial operations

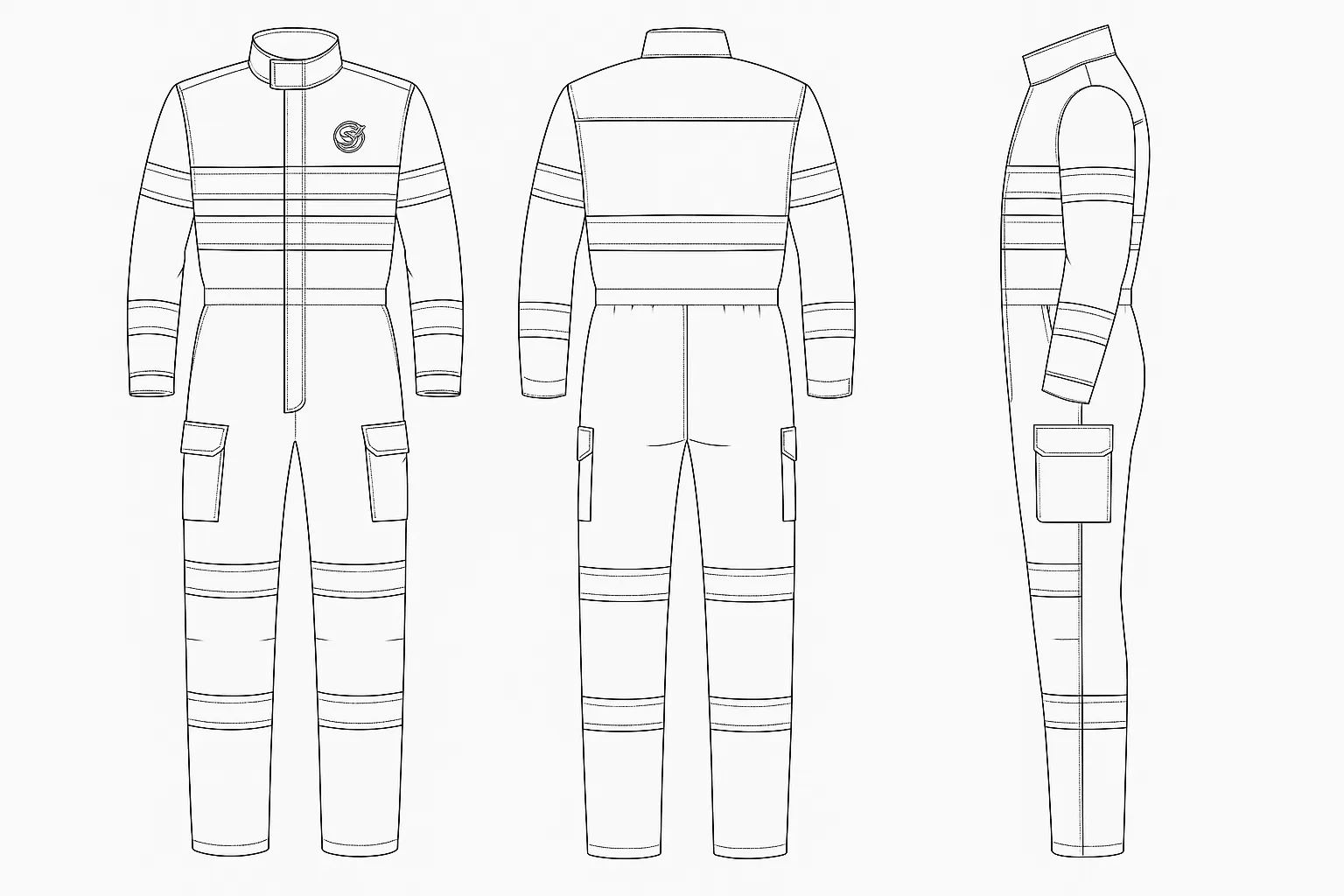

-Multiple utility pockets – chest, thigh, tool, and pen compartments

-Designed for oil & gas, chemical, energy, and maintenance environments

-Available in Navy, Orange, and FR Yellow colorways

4. Materials & Trims

- Outer Shell: 7–9 oz (≈240–300 gsm) FR cotton/nylon twill – inherent or treated flame resistance, breathable comfort

- Lining: Unlined (one-piece garment structure)

- Reflective Tape: Optional 5 cm FR segmented tape – EN ISO 20471 & NFPA 70E compliant

- Zippers & Trims: FR nylon coil zippers; non-conductive pullers; FR hook-and-loop adjusters

- Thread & Seams: Nomex® FR thread; double-stitched with bar-tacks at stress points

- Accessories: Plastic snaps / metal-free components for electrical insulation

5. Structure & Functional Design

- Silhouette: Straight-fit coverall with ergonomic sleeve and shoulder articulation for full-body mobility.- Pockets: Dual chest zip pockets; standard hand pockets with optional flaps; detachable ID window pocket.- Comfort: Action back pleats and vented back panel enhance movement and airflow; brushed tricot collar facing for comfort.- Closure & Access: Two-way FR front zipper with storm flap; adjustable sleeve and leg openings for optimal fit.- Reinforcement: Bar-tacks at stress points; triple-needle seams at critical zones; reinforced knees for durability.

6. Market Benchmarks References

- Helly Hansen / Mascot / Blåkläder — European FR coverall design and ergonomic zoning

- Carhartt / Dickies — Rugged American workwear aesthetics and reinforced construction

- Cintas — Industrial uniform durability and customization capability

- 3M™ Reflective — Wash-durable FR reflective performance

7. Selling Messages

- FR protection · Certified safety compliance

- Durable and breathable · Lightweight comfort

- Ergonomic mobility · All-day wearability

- Industrial compatibility · Uniform integration ready

- High value · Easy care maintenance

8. Function – Design – Validation

| Function | Design | Validation |

|---|---|---|

| Flame Resistance | 7–9oz FR cotton/nylon twill; inherent/treated FR; metal-free at skin contact | Certified to EN ISO 11612 / NFPA 2112; garment-level FR tests |

| Arc Protection | Arc-rated fabric; FR zipper & thread; insulated trims | NFPA 70E / ASTM F1506, IEC 61482-2; CAT 2 (ATPV ≥ 8–12 cal/cm²) |

| Full-Body Protection | One-piece coverall; double-stitched seams; stress-zone reinforcements | Seam strength / tear / abrasion tested; QC pull-tests |

| Mobility & Comfort | Ergonomic cut; elasticized waist; underarm gusset / back pleat | Wear trials under industrial conditions; range-of-motion checks |

| Durability | Triple-needle seams; bar-tacks; reinforced knees | Abrasion, tear, and seam-strength tested |

9. Retro-Reflective Area (M size example)

Approx. 0.15–0.22 m² (depending on tape configuration). EN ISO 20471 compliant when reflective option applied.

10. Compliance & Quality Assurance

-Material Compliance: All shell, and trim materials must comply with OEKO-TEX® Standard 100 Class II requirements, with supplier certificates and valid test reports provided.

-Testing & Performance: Key fabrics must undergo third-party testing for flame resistance, tensile and tear strength, abrasion resistance, colorfastness, and dimensional stability, with compliance reports referencing EN ISO, AATCC, or ASTM standards.

-Workmanship Standards: Stitch density, seam construction, and seam allowances must comply with international workwear standards, with reinforcements at all critical stress points.

-Labels & Care Instructions: Labels must include size, supplier, production date, material composition, and ISO 3758 care symbols, attached at regulated locations (e.g., back neck or side seam).

-Packaging: Each garment must be individually packed in recyclable polybags. Cartons must be clearly marked with SKU, size, color, origin, PO number, and barcodes.

-QA Documentation: Supplier must provide all relevant compliance documentation — including OEKO-TEX® certificates, performance test reports, and batch QA records — prior to shipment.