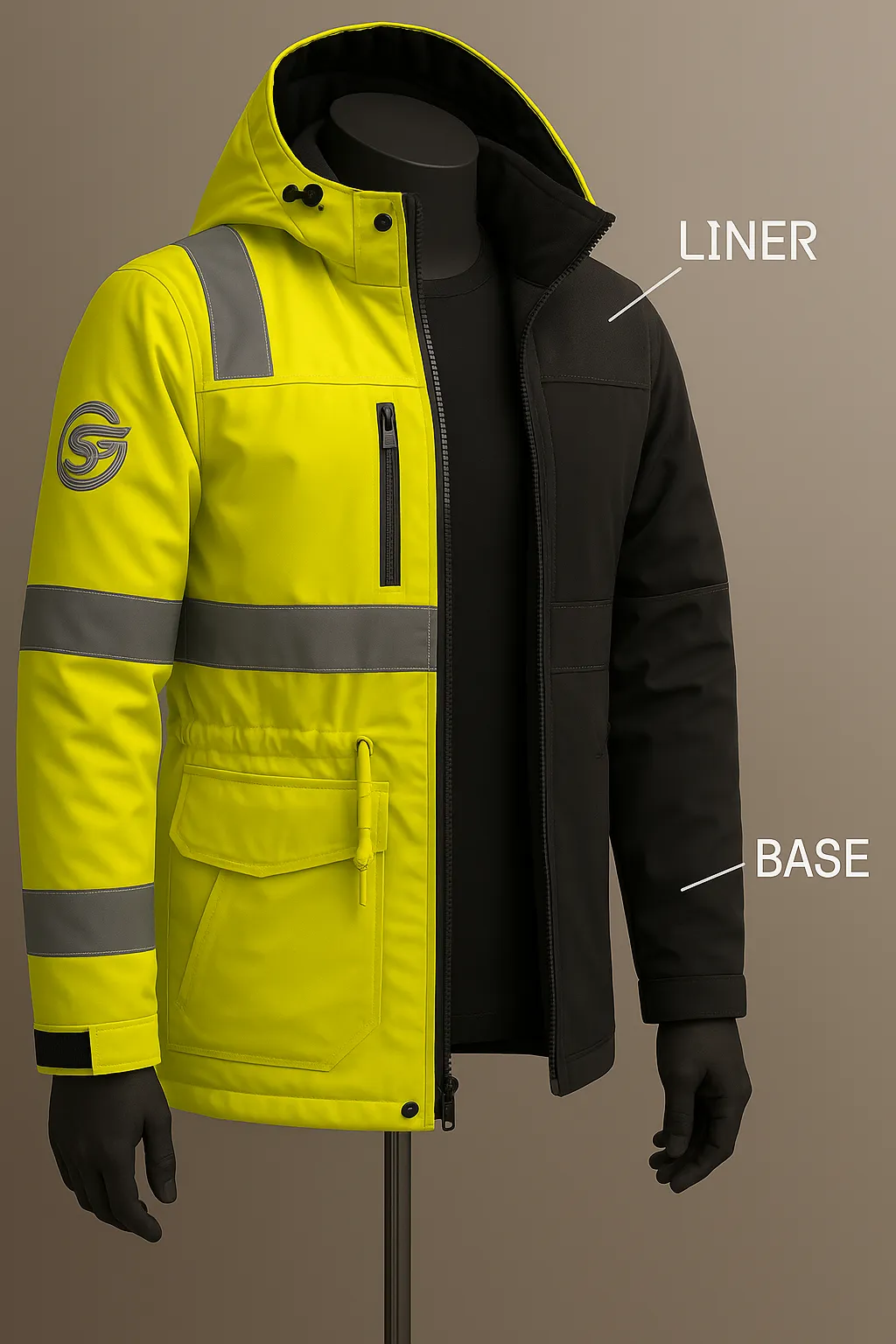

2175002 · SUMMA VANGUARD · Hi-Vis Shell Jacket

SPRING 2026 RELEASE · Professionally Engineered Workwear

Gallery

Click to enlarge · Swipe to switch

Details

2175002 · SUMMA VANGUARD · Hi-Vis Shell Jacket

2175002 · SUMMA VANGUARD · Hi-Vis Shell Jacket -

Keywords

All-weather visibility · Wind and rain protection · EU and North American worksites

1. Basic Information

- Product Code: 2175002

- Series: H = Hi-Vis

- Cost Anchor: USD $22–26 (FOB base specification, estimated)

- Compliance: ANSI/ISEA 107 Type R Class 3; EN ISO 20471 Class 3; EN 343

- Positioning: Four-season outer shell, designed for modular Zip-in liner compatibility

2. Application Scenarios

Municipal works , Traffic control , Logistics and warehousing , Construction and infrastructure , Night and adverse-weather operations

3. Technical Highlights

- Certifications: ANSI/ISEA 107-2020 Type R Class 3; EN ISO 20471 Class 3; EN 343 (target Class 3:1 or higher)

- Performance: Waterproof ≥ 8,000 mm; Breathability ≥ 5,000 g/m²/24h; Wash-durable retro-reflectivity

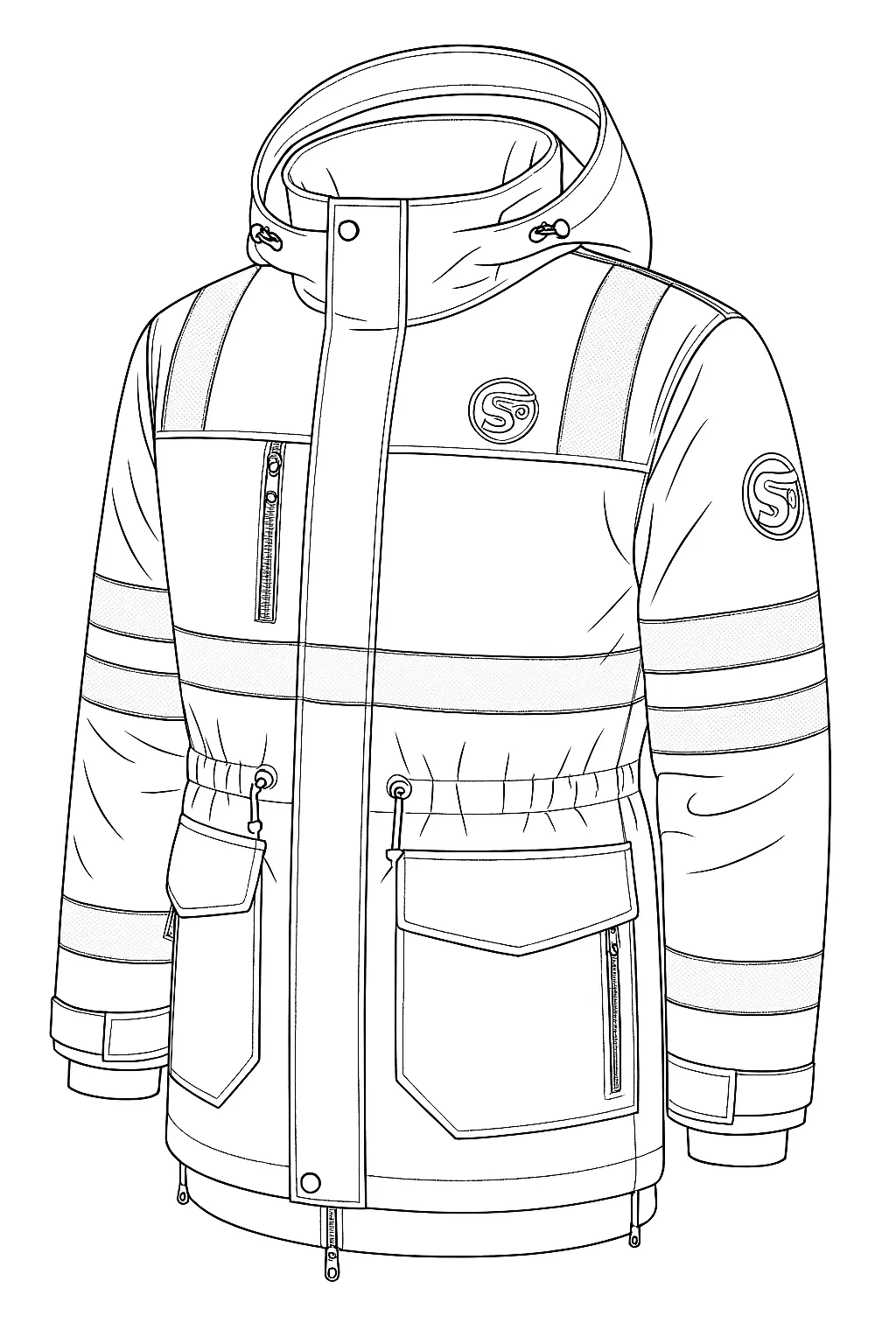

- Features: Waterproof and breathable; windproof; lightweight abrasion resistance; seam-sealed critical areas; high-visibility reflective identity; underarm ventilation; Zip-in modularity for four-season layering

4. Materials & Trims

- Outer Shell: 150–170 g/m² stretch polyester with PU/TPU membrane; C0/PFC-free DWR

- Lining: Black mesh (body); 210T/240T taffeta (sleeves/placket)

- Reflective Tape: 5 cm segmented reflective tape (washable 25–50x, 3M™ or equivalent)

- Zippers & Trims: #5 water-repellent zipper (front); #3 zipper (pockets); hook-and-loop adjustable cuffs; elastic hem drawcord with stoppers; 20 mm seam-sealing tape; polyester core-spun sewing thread

5. Structure & Functional Design

- Silhouette: Straight fit; ergonomic sleeve and shoulder cut; optional navy contrast paneling

- Pockets: Chest zip pocket; dual hand pockets (warm lining, optional flaps); inner secure pocket; detachable ID pocket

- Comfort: Underarm vents; mesh sweat channel; brushed tricot collar facing

- Hood: Detachable 3-piece hood with visored brim; standardized Zip-in liner system

- Reinforcement: Bar-tacks at stress points; triple-needle seams at critical zones

6. Market Benchmarks

- Cintas (Hi-Vis/Uniform): Fleet durability, customization, logo-ready

- Helly Hansen / Mascot / Blåkläder: Ergonomics, functional zoning, European reflective layout

- Carhartt / Dickies: Rugged aesthetics, reinforced construction, practical usability

- 3M™ Reflective: Wash-durable retro-reflectivity

7. Selling Messages

- ensp;All-weather visibility · Certified protection

- ensp;Rainproof and breathable · Lightweight comfort

- ensp;Ergonomic mobility · All-day wearability

- ensp;System modularity · Zip-in liners for 4-season use

- ensp;High value · Easy maintenance

8. Function – Design – Validation

| Function | Design | Validation |

|---|---|---|

| High-Visibility | Fluorescent yellow outer shell with 5 cm segmented reflective tape | Meets ANSI/ISEA 107-2020 Type R Class 3; EN ISO 20471 Class 3 |

| Weather Protection | 150–170 g/m² stretch polyester shell with PU/TPU membrane, seam sealing, C0/PFC-free DWR finish | Waterproof ≥ 8,000 mm; Breathability ≥ 5,000 g/m²/24h; EN 343 3:1 |

| Comfort & Mobility | Ergonomic sleeve/shoulder cut; breathable mesh; detachable hood; adjustable hem and cuffs | Wear trials; QC fit validation |

9. Retro-Reflective Area (M size example)

- Chest & Waist Rings: 1,100 cm² (two torso rings, approx. 110 cm circumference × 5 cm width)

- Sleeve Bands: 800 cm² (two bands × two sleeves × 40 cm circumference × 5 cm width)

Total: 1,900 cm² (≈ 0.19 m²). Meets EN ISO 20471 Class 3 minimum reflective area requirement (≥ 0.14 m² for size M).

10. Compliance & Quality Assurance

- Material Compliance: All fabrics and trims must comply with OEKO-TEX® Standard 100 Class II requirements, with supplier certificates and valid test reports provided.

- Testing & Performance: Key materials must undergo third-party testing for tear strength, abrasion resistance, colorfastness, dimensional stability, and waterproof/breathable performance, with compliance reports referencing EN ISO, AATCC, or ASTM standards.

- Workmanship Standards: Stitch density, seam allowances, and seam taping must comply with international workwear standards, with reinforcements at all critical stress points.

- Labels & Care Instructions: Labels must include size, supplier, production date, material composition, and ISO 3758 care symbols, placed at regulated positions (e.g., back neck or side seam).

- Packaging: Each garment must be individually packed in recyclable polybags. Cartons must be clearly marked with SKU, size, color, origin, PO number, and barcodes.

- QA Documentation: Supplier shall provide all required compliance documentation — including OEKO-TEX® certificates, performance test reports, and batch QA records — prior to shipment.